Logistics

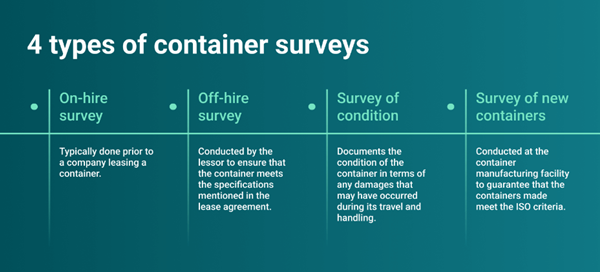

4 types of container surveys

JKMS offers inspection services to existing containers certified to efficiently trade within various modes of transport. Typically, a container is inspected and certified as an Intermodal container in order to operate between ship to rail to road or as an Offshore Container to operate between dock to ship to offshore facility. The in-service inspection is often referred to as an 2.5 or 5 year periodic inspection and the inspection is required to maintain the initial certifications provided during manufacture.

There are four types of container surveys that you’ll find helpful. You get an on-hire survey, an off-hire survey, a survey of condition and survey of old/new containers. Let’s break them down:

On hire survey

This survey is typically done before a company leases a container. It ensures that the container is in good condition and meets all of the conditions agreed upon by the lessor and lessee.

The surveyor focuses on existing damages and defects in the container. They consider these before classifying the container as fit for general cargo, food items, or any other classification required by the lessee.

This survey protects you from paying extra cash for the damages that you’re not responsible for. Here the container is inspected to determine pre-existing damages or defects. On hire survey is essential to avoid any conflicts with your lessor at the time of returning the container.

Off hire survey

This survey is conducted by the lessor after the leased container is returned. This is to check for damages outside the ones mentioned in the lease agreement between the lessor and the lessee. The container surveyor identifies any repairs that would be needed on the container, and the best way to go about it.

Survey of condition

The container surveyor documents the condition of the container in terms of any damages that may have occurred during its travel and handling in this sort of survey. This type of examination also considers the container’s general wear and tear.

A container surveyor determines if the container is acceptable for cargo storage and transit and, if not, the most cost-effective manner of utilizing the container, such as fixing it, returning it to the lessor, or scrapping it.

Survey of old/new containers

These are the surveys conducted at the container manufacturing facility to guarantee that the new containers that are manufactured meet the ISO criteria (International Standards Organization). Prior to the start of regular mass production at a container manufacturing site, new container surveys are performed. The container surveyor would next recommend adjustments to the manufacturing process or any other abnormalities discovered during the assessment.

Similarly, you can also have an inspection done for an old container to rule out any major damages and defects the box might have before a shipment.

ISO container inspection checklist

Container inspection determines if the container’s condition is acceptable for carrying or storing cargo. The inspector or surveyor will examine the container to ensure that it complies with all of the ISO intermodal transportation terms and conditions.

Cargo and container inspection is required at all customs offices to prevent and identify the entry of illegal objects into the country. However, it is not only that segment that may profit from using bulk inspection systems.

Four-point ISO inspection checklist

There are some crucial checkpoints that safety officials look for in ISO container inspections to avoid container damage.

|

ISO identification |

The ISO mark should be plainly visible on the shipping container’s top right corner as well as the roof. |

|

CSC plate |

To be permitted for shipping under customs seal and CSC safety approval, an ISO container must pass static longitudinal restraint, focused loads, and stacking tests. |

|

Shipping documents |

Officials also inspect shipping documents to ensure that the commercial invoice, packing list, and bills of lading correspond to the actual contents inside the ISO container. |

|

Cargo |

Safety officers should examine goods before and after packaging, as well as cargo holds prior to and after loading. |